In the grand scheme, motorcycle suspension systems are made up of springing and damping components. Springs are easy to imagine. They're just coiled steel wires shoved into the fork tubes or wrapped around shock bodies. Springs hold up the bike and support both the static load of the bike and the rider, but are also sized (or rated, if you prefer) to accommodate expected bump loads. Spring-rate selection is a fairly straightforward process, starting with the weight of the bike and the rider and skewed by intended use. Racing demands maximum chassis control and comparatively stiff springs, while touring dictates lighter springs.

A spring is rated by how much weight is required to compress it a certain distance. We're going to work in kilograms per millimeter, but if you're more comfortable in pounds per inch, simply multiply the stated numbers by 56. A heavy spring—one with a high rate—will be made of thicker wire wound into fewer coils. (Think of the spring uncoiled to help make this leap. A long rod is easier to bend if you put pressure on both ends than a short rod of the same thickness and material.) Motorcycle fork spring systems come in a variety of rates and three main styles. The first is called a straight-rate spring. This is a single spring with its coils are equally spaced, and it compresses in a linear fashion. Let's say you have a 1.0kg/mm spring. It takes one kilogram to compress it one millimeter. It takes another kilogram (two total) to compress it the second millimeter (two total). This holds true through the spring's entire useful travel, so that 50mm of movement requires 50kg.

Some suspension designers choose multiple-rate springs, which are made up of separate springs of different rates. A dual-rate system would have one light spring and one heavy spring placed end-to-end. This type of spring system responds like the softer-rate spring for the first part of the travel. Then, when this soft spring is compressed fullysaid to be coil-boundthe stiffer spring begins to compress. In this way you could have a spring rate of, say, 0.6kg/mm for the first part of the travel and a rate of 1.2kg/mm for the rest of the travel. Occasionally, there's a third spring in some fork systems, for three distinct rates.

Finally, there's the progressive option. This kind of spring is wound with its coils closer together on one end than the other. As the spring compresses, the close-wound coils eventually touch and take themselves out of the equation. The spring rate starts out light and becomesyou guessed itprogressively stiffer.

Springs are the first part of the equation, damping is the second. If we had just springs, it would be ugly. Every time the wheel hit a bump, it would compress the suspension. The spring temporarily stores up this energy but wants to release it as soon as possible, so it tries to extendor reboundpushing the front wheel away from the bike. But it will overshoot, and the suspension will continue in this up-down cycle for a surprisingly long time before settling down. (Watch a clapped-out taxi drive down a bumpy road for a graphic demonstration.) Of course, real roads have more than one bump, so this theoretical, damperless suspension would never settle down and never reach true equilibrium.

So we have mechanisms that create a very specific kind of resistance to suspension movement, called damping. Typically, these systems use oilgenerally very light oil compared to what's in the engine—forced through some kind of restriction. The amount of damping can be tailored depending on the size of the bump—meaning the displacement of the suspension component in question—as well as the sharpness of the bump. Quick hits such as those you experience rolling over sharp-edged pavement seams cause the suspension to move a small amount very quickly. Long-period disturbances, such as getting hard on the brakes, try to make the suspension move a lot but comparatively slowly. This is where we get the terms that define the speed of the suspension movement. When we say high-speed compression damping, we don't mean the speed of the vehicle, just the velocity of the suspension part in question. Generally, high-speed damping influences ride quality—what we perceive as harshness or chattering—while low-speed damping helps control chassis pitch—what you feel during hard acceleration or braking, as well as the gradual loading the suspension receives during aggressive cornering.

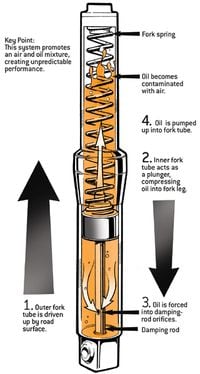

Most cruisers are in the Stone Age regarding fork technology. They use what's called a damping-rod fork, in which the damping action comes solely from oil being pushed around inside the fork and through sets of comparatively small holes. The big problem with a damping-rod fork is that it can be soft and underdamped during low-speed movement but suddenly turn harsh over the small stuff. This is because oil forced through a fixed-size hole offers resistance related to its velocity. When the oil is barely moving, there's little resistance. But try to force it quickly through a small hole and the resistance shoots way up.

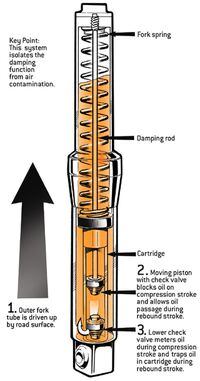

The technology that has superseded the damping-rod fork in sportbikes and a few cruisers is called a cartridge fork. One or both fork legs carry a small cylinder inside the lower section that is, basically, an open-chamber shock absorber. A piston slides through this cartridge, which is submerged in the fork oil. Small, flat metal discs called shims are stacked on top of the piston. As the suspension moves, the piston is forced through the oil, which in turn forces the shim away from the piston face. The thickness and diameter of the shim determines how much force is required to move it out of the way, and therefore how much damping you get. These shims can be fine-tuned to offer resistance even at low suspension speedsneeded to keep the chassis on an even keel—but also "blow off" sufficiently to allow the wheels to move rapidly in response to sharp bumps. The best of both worlds. In theory, anyway.

For more articles on how to maintain and modify your motorcycle, see the Tech section of MotorcycleCruiser.com.

/cloudfront-us-east-1.images.arcpublishing.com/octane/H6Z2IC7WYRBXZNQS4MI3SZ5KPQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/IWO5T5PBT5E4HFQ5GK47H5YXR4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/OQVCJOABCFC5NBEF2KIGRCV3XA.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/F3O2DGLA4ZBDJGNVV6T2IUTWK4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/ZXYQE3MHLFDSPKNGWL7ER5WJ4U.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/RDF24VM7WVCOBPIR3V3R4KS63U.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/W7RSIBFISNHJLIJESSWTEBTZRQ.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/AERA26ENRNBW3K324YWCPEXYKM.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/YWX3YX7QBBHFXFDMEEEKRG4XJE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/I7OKI53SZNDOBD2QPXV5VW4AR4.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/IH52EK3ZYZEDRD3HI3QAYOQOQY.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/K2FSAN7OWNAXRJBY32DMVINA44.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/G4XK7JL24FCUTKLZWUFVXOSOGE.jpg)

/cloudfront-us-east-1.images.arcpublishing.com/octane/JJNXVAC27ZCDDCMTHTQZTHO55Y.jpg)